What are Shrink Sleeve Labels? – Orianaa – The Best Label Manufactures in INDIA

What is Shrink Sleeve Labels, commonly known as Shrink Sleeve Labels, are heat-sensitive film substrates that take the complete shape of your container, offering 360-degree printability. Different grades of Shrink Films showing different shrinkages are available. With our three-decade expertise in the Shrink Film industry, Orianaa is proficient in suggesting the correct film for your container.

Everything is a little easier to understand with examples and images. Kindly refer images below to realize the different shapes of containers with other shrink film solutions

As we see above, Image A is a simple container, and we have used a standard cast film from our trusted vendor. In the case of image B, the container is extremely curvy, and we have used high shrink imported cast film.

Selection of the correct Shrink Film is possible only after a thorough sampling of the container. During the sample, our QA team has to select from a wide range of Shrink Film solutions, viz. PVC Cast Shrink Film, High Shrink PVC Cast Film, Imported High Shrink PVC Cast Film, PET Shrink Film, Imported OPS Film, and Imported Hybrid Film.

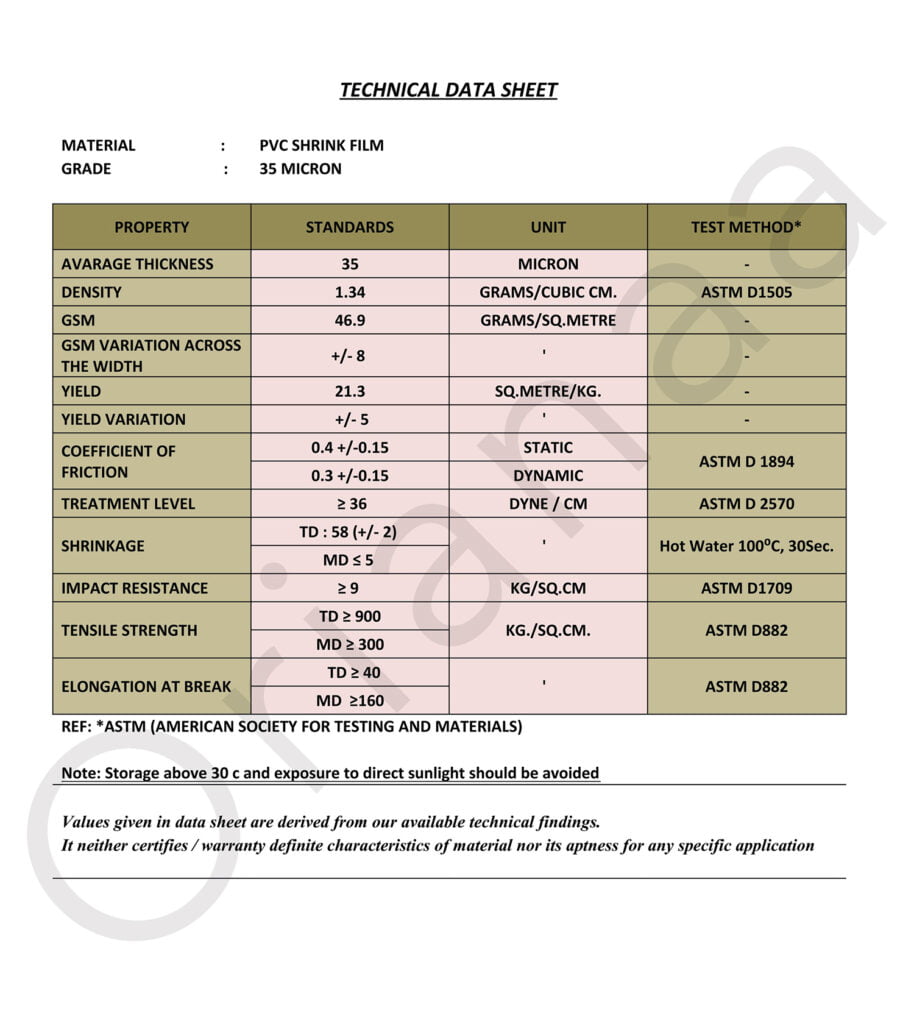

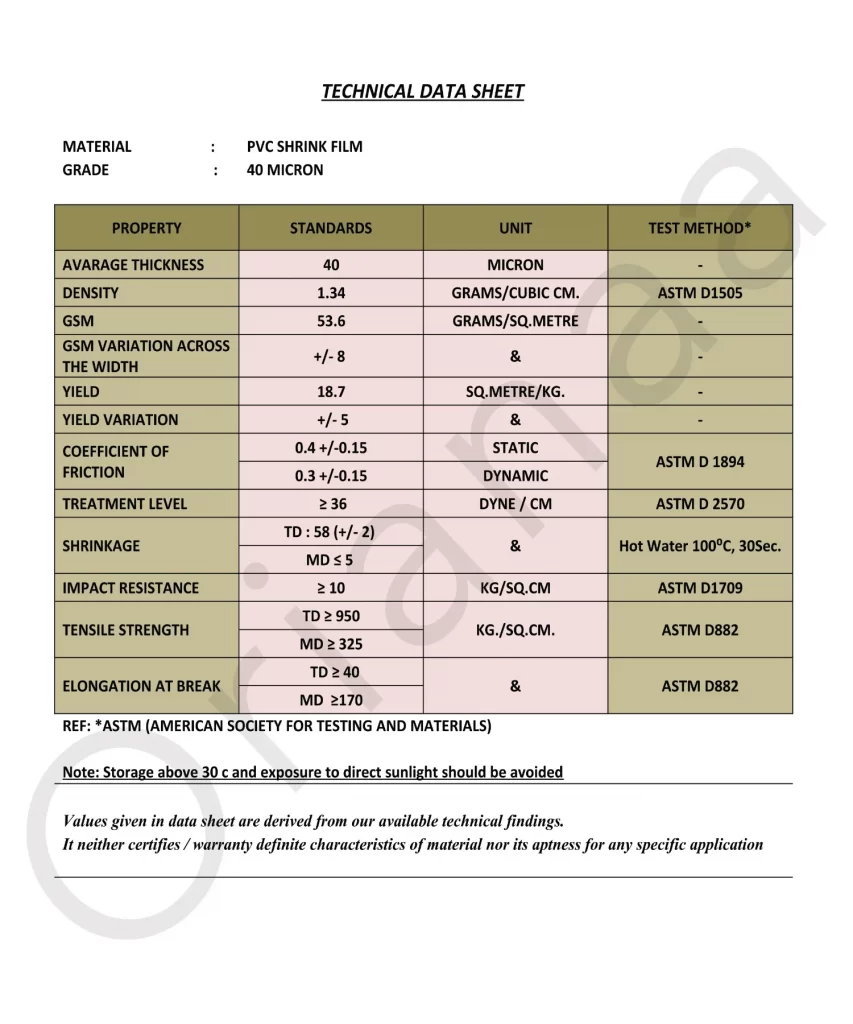

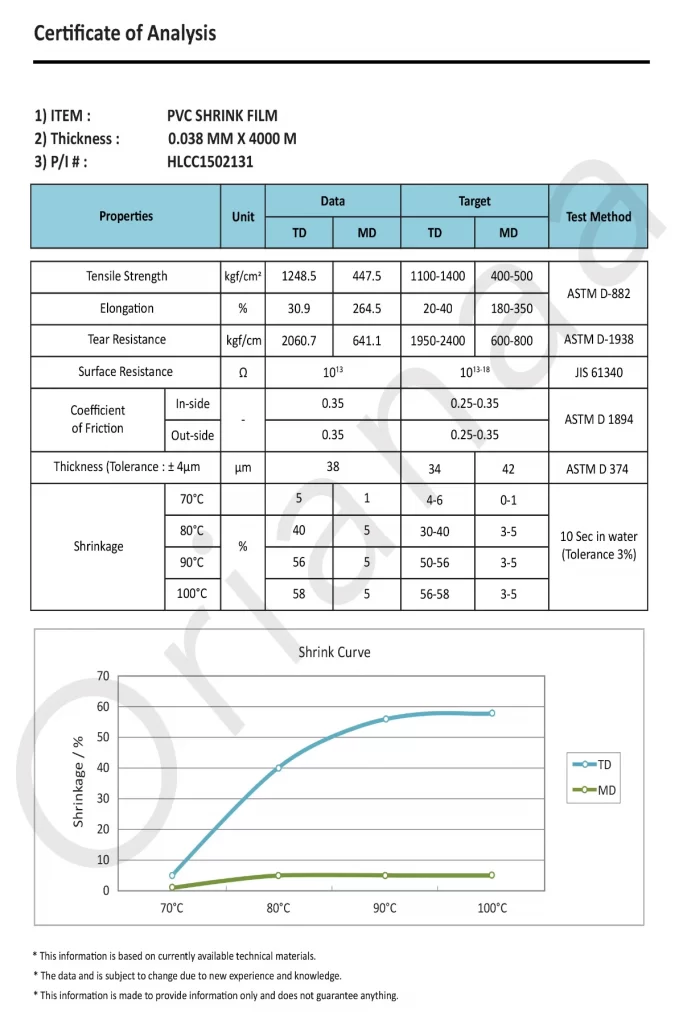

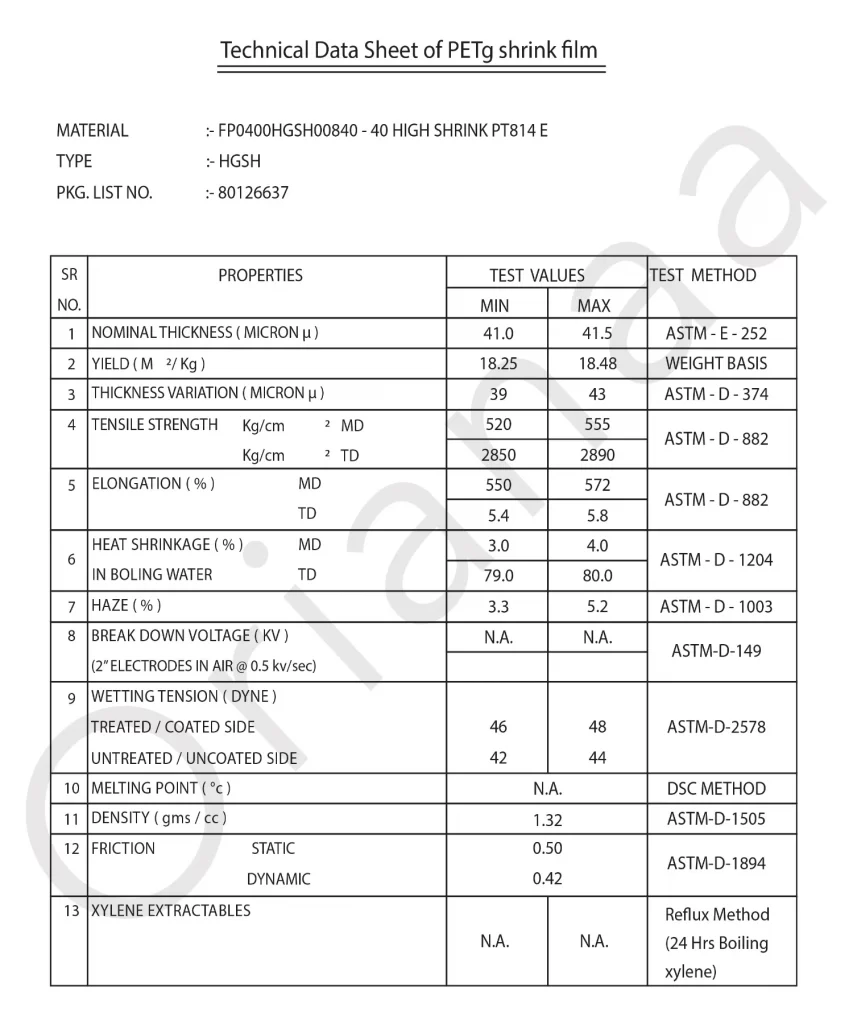

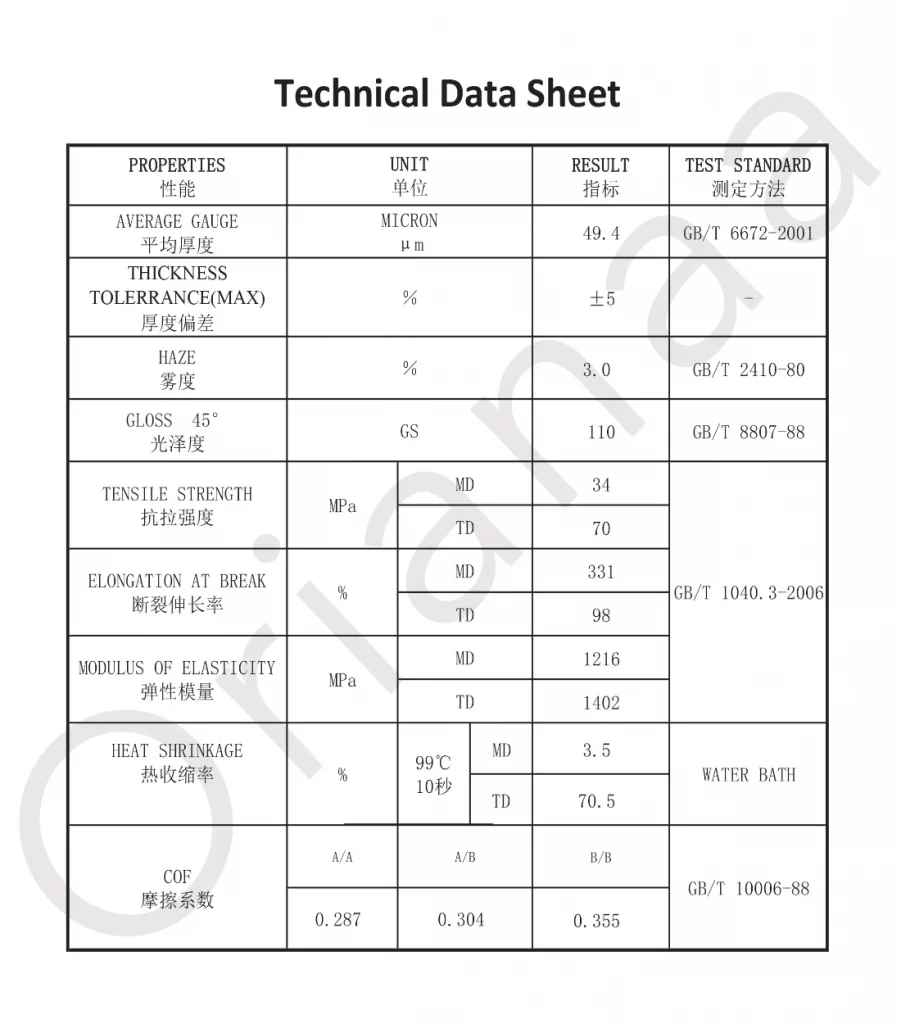

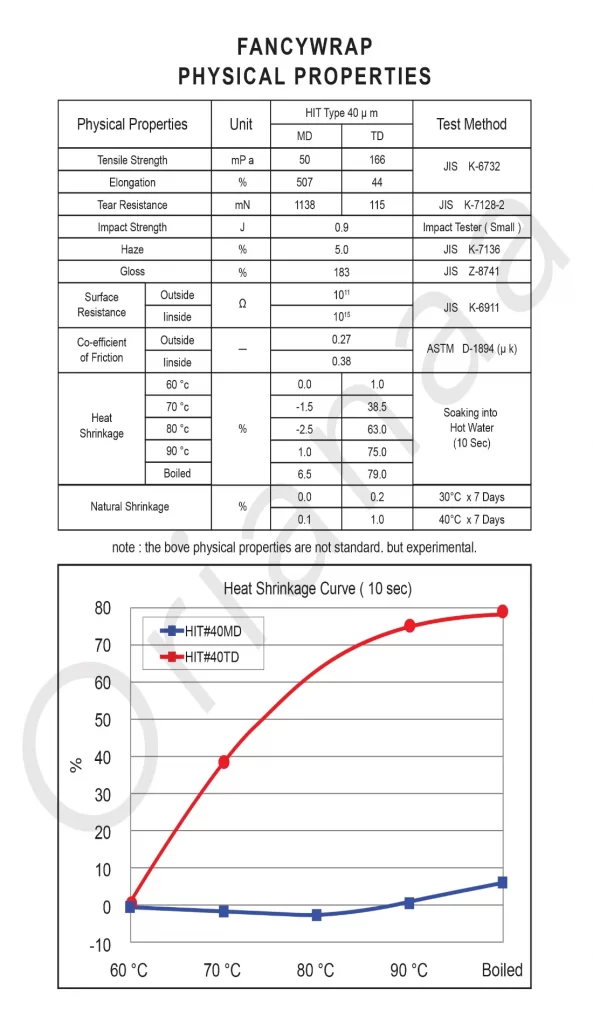

Please refer to the below TDS from our suppliers locally as well as abroad to understand the different types of Shrink Films available and which film was supplied to you by your printer.

Technical Data Sheet of different Shrink Sleeve Labels

1) PVC Cast Shrink Film (locally sourced)

Heat sensitive PVC film manufactured using the “Cast” technique for the best printability and consistency. Cast PVC film/PETg Film is the traditional medium of packaging in most developed countries. As of now, in India, Blown PVC Film (using a generic extruder) is highly dominant in the market, majorly due to local manufacturers who are highly focused on reducing costs. MNCs, on the other hand, has invested heavily in the quality and visual appeal of their products.

Usually, 40-micron thickness with shrinkage of 58% (2%variation) is preferred, although depending on your container, sampling will need to be conducted in order to be specific.

2) High Shrink PVC Cast Film (locally sourced)

As we saw earlier, heat-sensitive films with higher shrinkage properties are needed to decorate atypical containers or uniquely shaped jars, one of the most common grades in High Shrink Cast PVC with a shrinkage of 62% (2% variation) and available in 40 microns & above thickness.

3) Imported High Shrink PVC Cast Film

Sourced from Israel and Korea to achieve the best printability on PVC substrate and a shrinkage of 63% (2% variation). We insist on the usage of this grade only and only when locally sourced films are not giving us the desired result.

4) PETg Shrink Film

PET shrink film is considered to be a much more environmentally friendly alternative to PVC shrink film. Majorly used by all the MNCs in India.

5) Imported OPS Film

OPS, also called Oriented Poly-Styrene Film, is a low-density film that’s undergone a stretching process consisting in orienting the fibres in a specific direction, which is the direction in which the heat shrinking will occur. OPS is often used for containers that can be compressed easily. The pro part shrinks at temp. Helping avoid looseness of film on container post-cooling, unlike PETg. The con part must be stored, converted & dispatch under 27 degrees C.

Advantages of BOPS/OPS Film

· Superb clarity, spark, and gloss

· High rigidity, tear resistance

· Low specific gravity, 1.05 g/cm³

· Excellent anti-static ability

· Silicone coating – easier mold removal and stack nesting/denesting

6) Imported Hybrid Film

Hybrid(PET+OPS)Shrink film has both OPS and PET advantages. It’s a development of a more environmentally friendly shrink film. Hybrid Film is the most sustainable film environmentally but has a huge production cost which ultimately also makes this the most expensive shrinkable film.

When compared with OPS film

. Improved heat resistance

. Abrasion resistance

. Improved natural shrinkage

. Content tolerance

When compared with PET film

. Improved low-temperature shrinkage

. Tear line adaptation

. Reduced cost

7) Blown Shrink Film

The big bad villain of the shrink film industry. Hugely prevalent in developing countries of Africa, the Indian Sub-Continent, China, South America, and Indonesia. Highly disastrous to the environment, the standard of quality during production is negligent, drinkability is poor, and printability of colors is mostly misregistered. Yet, it is the most used film in India for branding and marketing for one reason only, it is incredibly cheap economically as well as qualitatively.

As per the core values of our founding and managing team, Blown Shrink Film has never been utilized by Oriana Decorpack or any of our group companies. This is due to excessive difficulties in printing which results in higher losses or defective supplies, both of which are against the code of ethics of our company.

The above Technical Data Sheets is for the awareness of the reader so that they are able to differentiate between different grades of Shrink Films, such that any mix-up in final supply shall be spotted upon random testing.